Our advanced infrastructure is built to meet the evolving needs of diverse industries with precision and efficiency. Featuring state-of-the-art machinery and cutting-edge automation, we ensure seamless operations, high-quality output, and improved productivity. Stringent quality control measures are applied at every stage to maintain the highest industry standards.

We offer tailored solutions to meet unique customer specifications without compromising on cost-effectiveness or efficiency. Innovation drives our continuous improvement in production and workflow, while optimized logistics enhance supply chain performance and delivery timelines. With skilled professionals and robust process management, our facility ensures consistent, reliable execution for both large-scale and specialized projects. Our commitment to sustainability ensures environmentally responsible practices across all operations. Advanced data analytics support proactive decision-making and operational transparency. We foster strong partnerships through clear communication and responsive customer service.

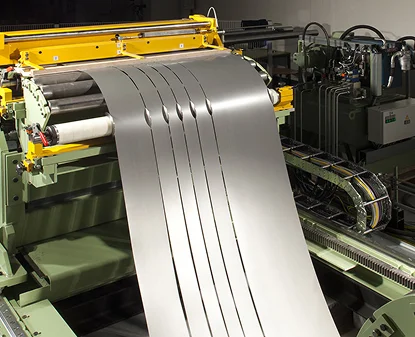

Designed for precision steel strip processing, enabling customized widths to suit specific applications.

Ensures tubes are cut to exact customer specifications, optimizing time, energy, and material costs.

Automatic Chamfering Lines – Designed for burr-free & export grade finished tubes.